The human-machine interface (HMI), is a key part of modern technology. It acts as a bridge between people and the automated systems they use. HMIs enable smooth communication between humans and machines.

They help operators monitor, control, and interact with complex processes. HMIs are especially important in industrial automation.

They have evolved from simple panels with buttons and dials to advanced touchscreens, 3D displays, and even virtual reality systems. This evolution has boosted safety, performance, and overall efficiency.

This article explains what an HMI is, describes its main types, and explores its role in industry. It also highlights the latest trends shaping the future of human-machine interaction.

What is a Human-Machine Interface?

An HMI is any device or software that lets a human interact with a machine, process, or system.

It works like a control dashboard that translates complex technical data into visuals that are easy to understand.

The user sends commands by touching a screen, pressing a key, or turning a dial. The HMI then converts those actions into signals the machine can follow. HMIs are most common in industrial control and automation.

However, they are also part of everyday life. The touchscreen on your smartphone, the display in your car, and the panel on a washing machine are all examples of HMIs.

Main Parts of HMI

The main parts of an HMI system include:

Input Devices

Tools the user uses to send commands, such as buttons, touchscreens, keyboards, or voice input.

Output Devices

Displays, indicators, and alarms that show results or give feedback.

Software

The program that defines how the HMI looks and works, making it simple and easy to use.

Connectivity

The network that allows the HMI to communicate with machines or controllers like PLCs and industrial systems.

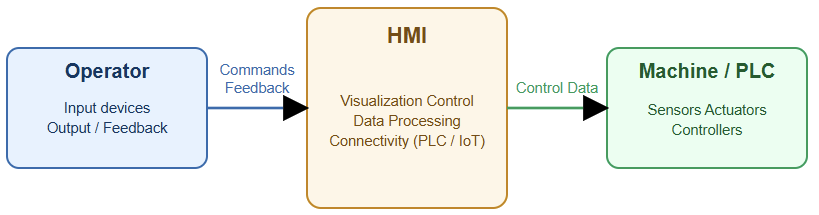

A figure below illustrates a diagram showing the main components of an HMI system. The arrows show information moving both ways between operator, HMI, and machine.

The Evolution of HMIs

The idea of HMIs has changed over the years, following major advances in technology.

Early Interfaces

The first HMIs were simple and mechanical. Operators used levers, switches, and analog gauges to control machines. They had to read values manually and make adjustments by hand.

This required time and experience and often led to mistakes. In the mid-20th century, early computer terminals started replacing some of these controls.

These were text based systems where operators typed commands. Using them required special training and technical knowledge.

Digital and Graphical Interfaces

In the 1970s and 1980s, new screens like LEDs and LCDs gave operators instant visual feedback.

This shift introduced graphical user interfaces (GUIs), which replaced command lines with visual icons, buttons, and menus.

HMIs became easier to use, even for non-experts. During this period, industrial PCs and touchscreen panels became popular.

They combined many functions that previously required large control walls full of switches and indicator lights.

Modern Interfaces

Modern HMIs use advanced technology for better performance and flexibility. High-resolution and multi touch screens make them intuitive.

Web based and cloud connected HMIs allow remote access from computers, tablets, and phones.

The rise of the Industrial Internet of Things (IIoT) has transformed how HMIs operate.

They can now collect and display data from hundreds of sensors and smart devices across a plant

Today, new technologies like augmented reality (AR) and voice control are taking HMIs to the next level. These tools create more natural and efficient ways for humans to interact with machines.

Types of Modern HMIs

Different types of HMIs are designed for specific environments and tasks.

Fixed or panel-mount HMIs are the most common type found in factories. They are installed directly on machines or control panels and built to withstand harsh industrial conditions.

Their durable design makes them reliable for continuous operation in demanding environments.

Industrial PCs (IPCs) are more powerful versions of HMIs. They handle complex processes that require higher computing and graphics performance. IPCs are often linked with larger automation systems such as SCADA, allowing advanced monitoring and data management.

Web-based and mobile HMIs offer the advantage of remote access. Operators can monitor and control equipment from any location using a standard web browser or mobile app.

This flexibility is especially useful for companies managing multiple sites or when quick access is needed off-site.

Embedded HMIs are integrated directly into a product or device. They appear in equipment such as medical instruments, car dashboards, and smart home appliances. These HMIs are compact, efficient, and designed for one specific purpose, providing smooth operation within their limited scope.

The Difference Between HMI and SCADA

The combo HMI and SCADA is often used together in automation, but they serve different purposes.

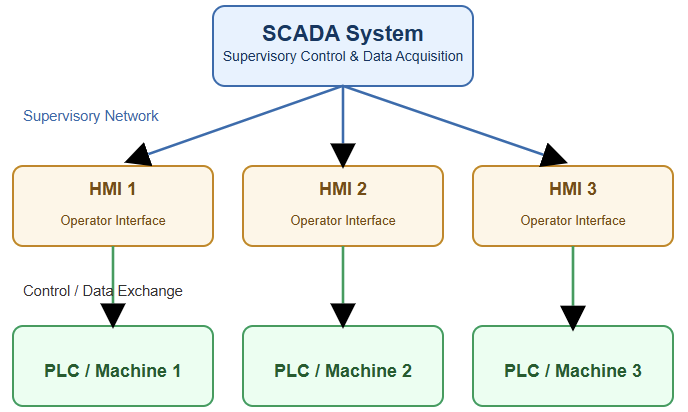

The HMI focuses on a single machine or process. It gives operators a visual interface to control and monitor equipment directly.

On the other hand, SCADA is a broader system that supervises and controls multiple HMIs or machines across an entire facility. In many cases, it can even manage operations across several locations.

It collects data from all connected systems and allows advanced analysis and centralized control.

The next figure indicates a diagram showing how an HMI connects to one PLC or machine. On other hand, a SCADA system manages several HMIs and machines together.

The Difference Between HMI and SCADA

The combo HMI and SCADA is often used together in automation, but they serve different purposes. The HMI focuses on a single machine or process. It gives operators a visual interface to control and monitor equipment directly.

On the other hand, SCADA is a broader system that supervises and controls multiple HMIs or machines across an entire facility. In many cases, it can even manage operations across several locations.

It collects data from all connected systems and allows advanced analysis and centralized control. The next figure indicates a diagram showing how an HMI connects to one PLC or machine. On other hand, a SCADA system manages several HMIs and machines together.

Key Principles of Effective HMI Design

A good HMI design always focuses on the user. This is particularly important in industrial settings, where speed, accuracy, and safety are critical.

Simplicity and clarity are key. Screens should be clean and easy to read. Clutter should be avoided so operators can react quickly and make decisions without confusion.

Consistency in design is also important. The interface should use the same style across all pages and systems. This approach reduces the learning curve and minimizes mistakes during operation.

Visibility and feedback ensure operators know what is happening at all times. Critical data must be clearly displayed, and the system should provide immediate confirmation when an action is taken. This helps prevent errors and reinforces correct operation.

Color scheme should be used intentionally. Colors can highlight warnings and important alerts. At the same time, overly bright or flashing colors should be avoided, as they can cause distraction and fatigue.

Ergonomics plays a crucial role in HMI design. Screen size, placement, and input controls should support operator comfort. Reducing physical strain improves focus and overall efficiency during extended use.

The Benefits of Effective HMI

A well designed HMI provides many advantages across industries. One of the main benefits is higher efficiency and productivity.

By simplifying complex processes and offering intuitive controls, HMIs help operators make decisions faster. This reduces downtime and keeps operations running smoothly.

Another important benefit is enhanced safety. HMIs provide real-time alerts that warn operators about potential hazards or equipment issues.

Quick responses to these alerts can prevent accidents and improve workplace safety.

Data driven decision making is also a key advantage. Modern HMIs collect and display large amounts of operational data.

Engineers and managers can analyze this information to identify trends, optimize processes, and make smarter decisions that improve overall performance.

Customization and flexibility make HMIs even more effective. Interfaces can be tailored to show only the most relevant information for a specific task or user role. This focus makes the system easier to use and more efficient for each operator.

Finally, remote monitoring and control allows operators to oversee systems from anywhere. Web based and mobile HMIs enable access off-site, which is especially useful for facilities with multiple locations or during emergencies.

This flexibility ensures that critical systems can be managed even when operators are not physically present.

The Future of HMI

The future of HMIs is full of innovation, with new technologies shaping how humans interact with machines. One major trend is the use of artificial intelligence (AI) and machine learning.

HMIs will become smarter and more proactive. They will not only display data but also analyze it, predict problems, and suggest actions to prevent issues before they occur.

Augmented reality (AR) and virtual reality (VR) are also transforming HMIs. These technologies provide more immersive and intuitive ways to interact with complex systems.

For example, a technician could use smart glasses to view real-time diagnostics or step-by-step instructions while repairing a machine.

Voice and gesture control is another emerging feature. As recognition technologies improve, operators will be able to control systems hands free.

This is especially useful in environments where hands must remain free or in sterile settings, such as hospitals or laboratories.

Future HMIs will focus on accessibility and inclusivity. Interfaces will be designed to support a wider range of users, including those with disabilities. This will involve adaptable layouts, voice guidance, and customizable input options.

Finally, HMIs will become more integrated and context aware. Instead of being confined to a single device, they will operate across multiple platforms.

They will use information such as user location, role, or task context to show relevant data at the right time.

This proactive approach will make human-machine interaction faster, smarter, and more intuitive.

Key Takeaways: What is Human-Machine Interface?

This article explored the human-machine interface as more than just a screen. It is a vital bridge for communication between people and automated systems.

HMIs have come a long way, from mechanical switches to smart, AI-powered interfaces.

They continue to evolve to improve performance, safety, and ease of use. With good design and modern tools like IoT, AR, and voice control, engineers can build interfaces that make complex operations simple.

They also help people work smarter and more efficiently. As technology advances, the bond between humans and machines will grow even stronger.

A well designed HMI will remain a key part of that connection, shaping the future of how we work with machines.

FAQ: What is Human-Machine Interface?

What is an HMI?

An HMI is the hardware or software interface through which a human operator interacts with a machine, system, or process.

Why are HMIs important?

They provide operators with visual feedback and control over machinery, improving efficiency, safety, and decisionmaking in industrial environments.

How have HMIs evolved?

HMIs have progressed from mechanical controls and analog indicators to graphical displays, touchscreens, web/mobile access, and integration with IIoT devices.

What is the difference between HMI and SCADA?

HMI focuses on the interface for a single machine or process. SCADA refers to a system that monitors and controls multiple machines or sites and uses HMIs as part of its interface.

Where are HMIs used?

They are used in industrial systems, manufacturing, and any scenario where a machine needs human control and monitoring.

How does an HMI work?

It takes user input (like touches or keystrokes) and converts it into commands the machine can execute.