A Programmable Logic Controller (PLC) is a specialized computer used in industrial applications. It is designed specifically to survive in harsh industrial environments and to control machines and processes reliably.

The PLC works as the brain of automation, ensuring that every input is monitored and every output is controlled according to programmed logic.

The PLC needs to work quickly because industrial processes often demand immediate and precise actions.

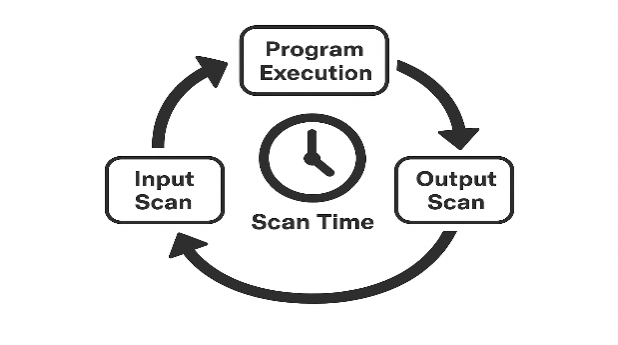

To achieve this, the PLC performs a continuous loop of operations without pause. This loop is called a scan cycle, and it repeats constantly as long as the PLC is powered and in run mode.

The time it takes for one full loop to complete is known as the scan time. Even though the scan time is often measured in milliseconds, it makes a huge difference in how responsive and accurate a system can be.

This article will explain in detail what scan time is. It will also cover why scan time matters, what factors affect it, and how engineers can optimize it for better performance.

The Scan Cycle: A Three-Step Process

The scan cycle is the heart of a PLC’s work. It is what allows the controller to continuously read inputs, make decisions, and update outputs. The process involves three main steps that repeat over and over.

Input Scan

The PLC first reads the status of all input devices connected to it. These devices may include sensors, push buttons, switches, limit switches, proximity sensors, or any other type of input.

The PLC checks each device almost at the same instant and takes a “snapshot” of all inputs.

It saves this information in its memory, usually in an internal area called the Input Image Table or Process Image Input (PII).

The stored data is then used throughout the rest of the scan cycle. This method prevents errors caused by inputs changing during program execution.

For example, if a button is pressed and released very quickly, the PLC will still register its state during the snapshot, ensuring consistency.

Program Execution

Next, the PLC runs the user program that was written and downloaded by the engineer.

This program is often written in ladder logic, structured text, or function block diagram depending on the application.

The CPU processes the instructions step by step in the order they are arranged. During this stage, the PLC does not read the real inputs directly. Instead, it uses the values stored in the Input Image Table.

This design ensures stable decision-making without interference from rapidly changing inputs.

Based on these values, the PLC updates a different section of memory called the Output Image Table or Process Image Output (PIO).

For example, the program might check if a start button is pressed and a safety sensor is clear.

If both conditions are true, the PLC sets a coil in the Output Image Table that will later energize a motor starter.

Output Scan

Finally, the PLC updates the output devices. It takes the data from the Output Image Table and sends the actual signals to actuators, relays, solenoids, indicator lamps, alarms, or motor drives.

This ensures that the physical world reflects the logic decisions made in the program.

For example, if the Output Image Table indicates that a motor coil should be energized, the PLC will activate the corresponding output terminal and power the motor.

After completing these three steps, the cycle repeats immediately. Modern PLCs can complete thousands of these cycles per second, but the exact speed depends on the PLC model and program size.

Why Scan Time is Important

Scan time is a critical performance measure because it directly affects how the PLC controls a system.

A small change in scan time can make a big difference in system responsiveness and reliability.

System Responsiveness

A shorter scan time means the PLC can react faster to changes in inputs. This is crucial for high-speed machinery such as packaging lines, bottling plants, or pick-and-place robots.

If the scan time is too slow, the PLC might not respond in time, leading to missed cycles or mechanical faults.

Precision Control

Many processes need precise and continuous adjustments. Examples include motion control systems in robotics, dosing in chemical plants, or temperature control in furnaces.

A shorter scan time allows the PLC to make more frequent updates and corrections, improving accuracy.

Performance and Safety

In safety-critical applications such as emergency stops or conveyor belt protection, a slow scan time can be dangerous.

Even a delay of a few milliseconds could prevent an emergency stop from engaging quickly enough.

Monitoring and managing scan time is therefore essential for operator safety.

Avoiding Missed Events

Some input signals, such as pulses from an encoder or a high-speed sensor, can occur much faster than the scan time.

If the PLC is not fast enough, it can miss these pulses completely. This can cause incorrect counts, positioning errors, or faulty operations.

Factors That Influence Scan Time

Many things can affect how fast a PLC completes its scan cycle. Understanding these factors helps in both troubleshooting and designing efficient programs.

Program Complexity

A simple program with a few instructions runs quickly, while a long and complex program with many nested conditions, loops, or calculations takes more time.

For instance, a program that includes PID control, data logging, or advanced motion functions will increase the scan time compared to a basic on/off control program.

Number of I/O Devices

Each input and output adds to the scan time because the PLC must check or update every point.

A system with hundreds of I/O points will naturally take longer than a system with just a handful.

CPU Performance

Just like in a computer, the processor speed of the PLC matters. A modern high-speed PLC can execute instructions in microseconds, while older models may take much longer.

Communication Overhead

Many PLCs communicate with external devices such as HMIs, SCADA systems, robots, or other controllers.

The time spent exchanging data can add to the scan time, especially if there is heavy network traffic.

Special Instructions

Not all instructions are equal. Floating-point calculations, trigonometric functions, or data conversions require more processing time than simple Boolean logic.

System Health and Diagnostics

The PLC also performs background tasks like memory checks, fault diagnostics, and error handling. These small tasks, though necessary, slightly increase the total scan time.

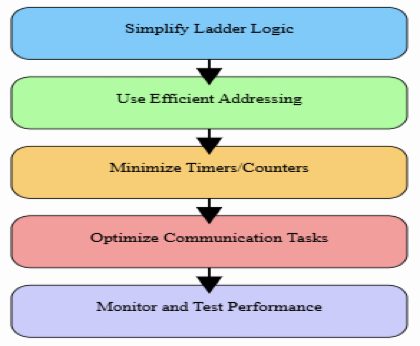

How to Optimize Scan Time

In many cases, the standard scan time provided by the PLC is enough for normal operation.

However, for high-speed or time-critical applications, engineers may need to optimize.

Use Subroutines

Organize your program into subroutines. You can call or skip sections of logic depending on need.

This prevents the PLC from wasting time on code that is not always required, reducing the average scan time.

Optimize Logic

Write programs as efficiently as possible. Avoid unnecessary instructions, repeated calculations, or redundant rungs.

Place the most likely conditions at the start of each rung so that the PLC can skip evaluating the rest if unnecessary.

Use Integers over Floats

Where possible, use integer data types for calculations. Integer math is much faster than floating-point math, especially on lower-end PLCs.

Upgrade Hardware

If scan time remains too long, upgrading to a modern PLC with a faster processor or more memory may be the best solution.

This is often necessary in applications involving robotics, high-speed packaging, or CNC systems.

Use Interrupts for High Speed

Some tasks cannot wait for the regular scan cycle. For these, PLCs provide interrupts, special events that pause the normal program and immediately execute critical logic.

Interrupts are commonly used for high-speed counters or emergency stop inputs.

Avoid Unnecessary Tasks

Minimize communication and background tasks that happen every scan. For example, data logging can be set to occur every second instead of every cycle. This reduces unnecessary load.

Key Takeaways: What is Scan Time in PLCs?

Scan time is a simple concept with very big implications in industrial automation. It represents the time a PLC takes to perform one complete cycle of operations: reading inputs, executing the program, and writing outputs.

Even though scan times are often very short, they determine how fast and accurately a system responds.

A short scan time is key for fast, precise, and safe control. Many factors affect scan time, including program size, I/O count, CPU speed, and communication load. By understanding these factors and applying optimization techniques, engineers can design more reliable and efficient automation systems.

In modern industries where milliseconds matter, mastering scan time ensures that machines perform safely, efficiently, and exactly as intended.

FAQ: What is Scan Time in PLCs?

What is PLC scan time?

PLC scan time refers to the duration it takes for a PLC to complete one full cycle of operations: reading inputs, executing the control program, and updating outputs. This cycle is crucial for the PLC to monitor and control industrial processes effectively.

How long is a typical PLC scan time?

PLC scan times can vary widely, typically ranging from 1 millisecond to 50 milliseconds, depending on factors such as the complexity of the control program, the number of inputs and outputs, and the processing capabilities of the PLC.

What factors affect PLC scan time?

Several elements can influence the scan time of a PLC:

- Program Complexity: More complex programs with numerous instructions or loops require more processing time.

- Number of Inputs and Outputs: A higher count of I/O points increases the time needed to read inputs and update outputs.

- Processor Speed: Faster processors can execute instructions more quickly, reducing scan time.

- Communication Overhead: Time spent communicating with external devices or networks adds to the total scan time.

- Instruction Types: Certain instructions, like floating-point calculations, take longer to execute than simpler ones.

Why is scan time important?

Scan time is critical because it determines how quickly a PLC can respond to changes in the process.

A shorter scan time allows for faster reaction to input changes, leading to more precise control and improved safety in time-sensitive applications.

How can I reduce PLC scan time?

To optimize scan time:

- Simplify the Program: Reduce unnecessary instructions and optimize logic to streamline execution.

- Use Efficient Data Types: Opt for integer operations over floating-point calculations where possible.

- Organize Code with Subroutines: Modularize the program to isolate tasks and reduce the overall scan time.

- Upgrade Hardware: Consider using a PLC with a faster processor or more memory to handle complex tasks more efficiently.

- Minimize Communication Delays: Limit the frequency and volume of data exchanges with external devices to reduce overhead.

How can I monitor PLC scan time?

Many PLCs provide diagnostic tools or built-in functions to monitor scan time. By regularly checking this parameter, you can assess the performance of your control system and identify areas for improvement.