A solenoid valve is a type of valve that uses electricity to control the flow of a fluid whether it’s a gas or a liquid.

It’s essentially a switch for fluid systems, turning flow on or off or redirecting it, depending on how it’s designed.

What makes it special is the solenoid, an electromagnetic coil that activates the valve mechanism.

How a Solenoid Valve Works?

Solenoid valves are the unsung heroes of modern automation. Whether it’s your dishwasher, a car’s fuel injector, or a massive industrial refrigeration system, solenoid valves quietly and efficiently control the flow of fluids using a clever combination of electricity and mechanics. But how exactly do they work? Let’s break it down in detail.

The Basic operating principle of a selenoid valve

At its core, a solenoid valve is an electromechanical device that controls the flow of a liquid or gas. It consists of two main parts:

The Solenoid

An electromagnetic coil that generates a magnetic field when electricity passes through it.

The Valve Body

A mechanical structure that opens or closes to regulate fluid flow.

The solenoid acts as the actuator, while the valve body is the part that physically blocks or allows fluid to pass.

When the solenoid is energized (i.e., electricity is applied), it creates a magnetic field that moves a metal plunger inside the coil. This movement either opens or closes the valve, depending on its design.

Step-by-Step Operation

Let’s walk through the process:

- Resting State: In its default state (either open or closed), the valve remains static. A spring holds the plunger in place.

- Energizing the Coil: When an electric current flows through the solenoid coil, it generates a magnetic field.

- Plunger Movement: The magnetic field pulls the plunger toward the center of the coil.

- Valve Activation: This movement either opens or closes the valve, allowing or stopping fluid flow.

- De-energizing: When the current stops, the magnetic field collapses, and the spring returns the plunger to its original position.

This entire process happens in milliseconds, making solenoid valves ideal for rapid and precise control.

Types of Solenoid Valves

Solenoid valves can be categorized based on how they operate:

Direct-Acting Solenoid Valves

- The solenoid directly moves the plunger to open or close the valve.

- Suitable for low-pressure systems and small flow rates.

- Simple design, fast response.

Pilot-Operated Solenoid Valves

- Use system pressure to assist in valve movement.

- The solenoid controls a small pilot valve, which in turn controls a larger diaphragm or piston.

- Ideal for high-pressure or high-flow applications.

- More energy-efficient since the solenoid doesn’t need to exert much force.

Normally Open vs. Normally Closed

Solenoid valves are also defined by their default state when not energized:

- Normally Closed (NC): The valve blocks flow until the solenoid is energized.

- Normally Open (NO): The valve allows flow until the solenoid is energized to close it.

This distinction is crucial when designing systems that must fail-safe in a particular way—such as shutting off gas flow during a power outage.

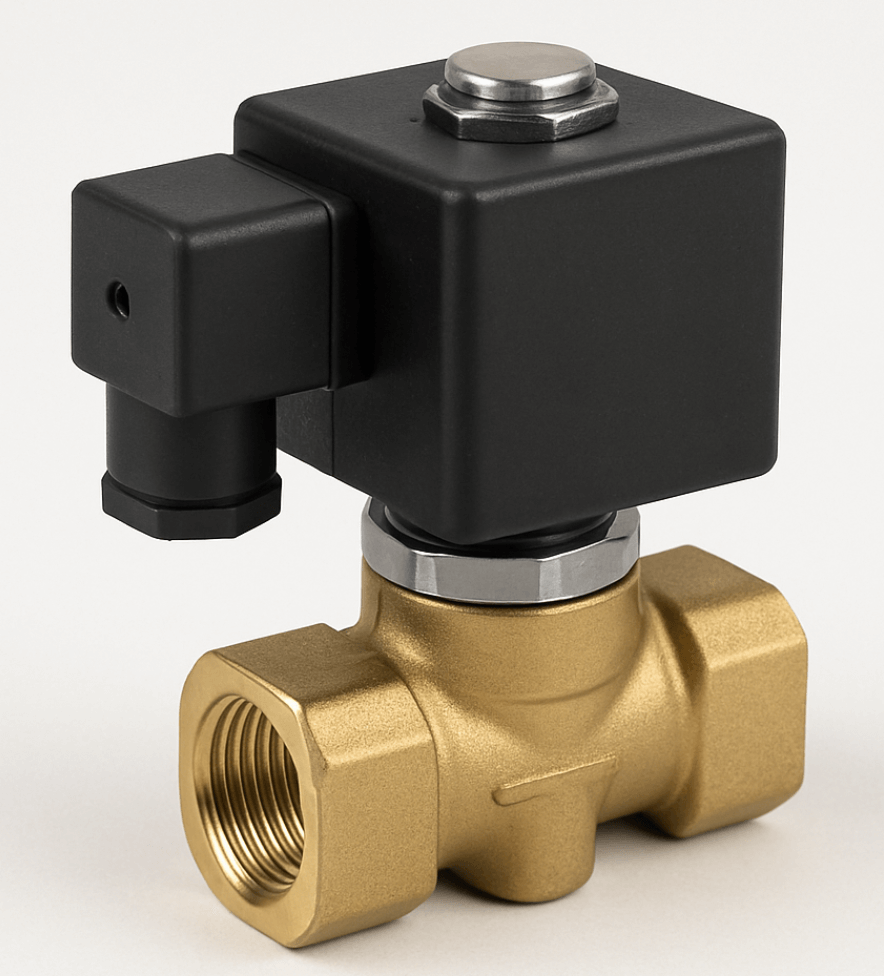

Materials and Construction

Solenoid valves are built using materials suited to their application:

- Valve Body: Brass, stainless steel, plastic, or aluminum.

- Seals: Rubber, PTFE, or other elastomers depending on fluid compatibility.

- Coil: Copper wire insulated and encased in a protective housing.

The choice of materials affects durability, corrosion resistance, and fluid compatibility.

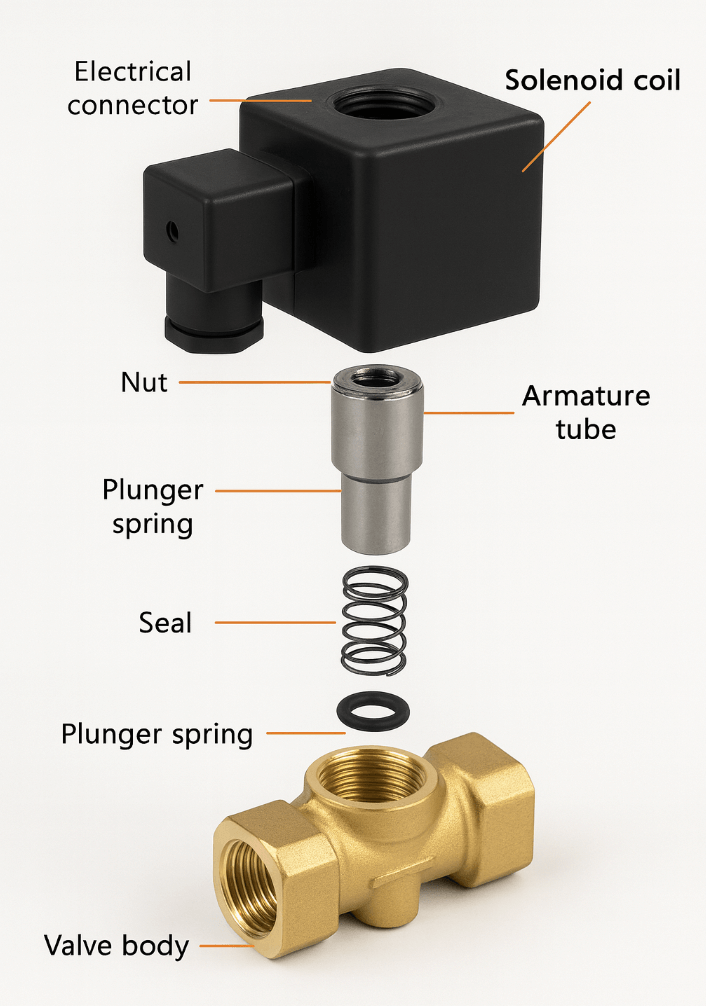

Key Components of a solenoid valve

Valve Body

- Function: The main housing that contains all internal components.

- Material: Typically made from brass, stainless steel, aluminum, or durable plastics.

- Design: Includes pathways for fluid to enter and exit, and supports the mechanical structure.

- Importance: It must withstand pressure, temperature, and chemical exposure depending on the application.

Inlet and Outlet Ports

- Inlet Port: Where the fluid enters the valve from the upstream system.

- Outlet Port: Where the fluid exits toward the downstream system.

- Threading: Often features NPT (National Pipe Thread) or other standardized fittings to ensure leak-proof connections.

Orifice

- Definition: A small opening inside the valve body that connects the inlet and outlet.

- Role: Controls the actual flow of fluid—when the valve is open, fluid passes through; when closed, flow is blocked.

- Size: The diameter of the orifice affects flow rate and pressure drop.

Solenoid Coil

- Core Function: The heart of the valve’s actuation system.

- Structure: A tightly wound copper wire that generates a magnetic field when energized.

- Encasement: Protected by a housing to prevent damage and ensure insulation.

- Purpose: Converts electrical energy into magnetic force to move the plunger.

Plunger (Armature or Piston)

- Function: A movable metal rod that responds to the magnetic field generated by the coil.

- Action: Moves vertically to open or close the orifice.

- Material: Usually made of ferromagnetic metals like stainless steel.

- Interaction: Directly influenced by the coil’s magnetic field and the spring’s mechanical force.

Spring

- Purpose: Returns the plunger to its default position when the coil is de-energized.

- Behavior:

- In normally closed valves, it pushes the plunger down to block flow.

- In normally open valves, it holds the plunger up to allow flow.

- Importance: Ensures reliable operation and consistent valve behavior.

Seals and Gaskets

- Function: Prevent fluid leakage and ensure tight sealing between components.

- Material: Often made from rubber, PTFE (Teflon), or other elastomers.

- Placement: Located around the orifice, plunger, and ports.

- Durability: Must resist wear, chemical corrosion, and temperature fluctuations.

Core Tube (Guide Tube)

- Role: Encases the plunger and guides its movement.

- Material: Non-magnetic stainless steel to allow magnetic field penetration.

- Design: Ensures smooth, frictionless motion of the plunger.

Electrical Connector

- Purpose: Provides the interface for electrical power to reach the coil.

- Types: May include DIN connectors, flying leads, or terminal blocks.

- Safety: Often includes insulation and waterproofing features for industrial environments.

Optional Components (Depending on Design)

- Manual Override: Allows manual operation during power failure.

- Pilot Valve: In pilot-operated valves, this small valve controls a larger diaphragm or piston.

- Diaphragm: Used in some designs to isolate fluid and assist in valve movement.

Common Application of a solenoid Valve

Solenoid valves are widely used in modern technology and industry because they offer fast, reliable, and automated control of fluid flow.

These valves use an electromagnetic coil to open or close a passage, allowing or stopping the flow of liquids or gases.

Their versatility makes them suitable for a wide range of applications across different sectors, from household appliances to complex industrial systems.

Industrial machinery

In manufacturing plants, solenoid valves help control the flow of fluids such as water, oil, air, and chemicals.

They are used in systems that require precise dosing, mixing, or distribution of substances.

For example, in beverage factories, solenoid valves regulate the amount of liquid poured into bottles. In chemical processing, they help mix different fluids in exact proportions.

Their ability to respond quickly to electrical signals makes them ideal for automated production lines where timing and accuracy are critical.

Automotive industry

Solenoid valves play a crucial role in vehicle operation and safety. They are used in fuel injection systems to control the amount of fuel delivered to the engine.

This helps improve fuel efficiency and reduce emissions. Solenoid valves are also found in automatic transmission systems, where they regulate hydraulic fluid to shift gears smoothly.

In braking systems, especially anti-lock braking systems (ABS), solenoid valves manage the pressure of brake fluid to prevent wheel lock-up during sudden stops.

Additionally, they are used in climate control systems to regulate coolant flow and maintain comfortable cabin temperatures.

Home appliances

These are another area where solenoid valves are commonly found. In washing machines and dishwashers, solenoid valves control the flow of water into the appliance.

When the machine starts a cycle, the valve opens to let water in and then closes when the desired level is reached.

This automation ensures efficient water usage and prevents overflow. Coffee makers and ice machines also use solenoid valves to dispense water or steam at the right time.

Their compact size and low power consumption make them perfect for household devices that require precise fluid control.

Refrigeration and HVAC systems

Solenoid valves are used to manage the flow of refrigerants. These systems often have multiple zones or compartments that need individual temperature control.

Solenoid valves open or close to allow refrigerant to flow to specific areas, helping maintain desired temperatures.

In air conditioning units, they regulate the flow of coolant to ensure efficient cooling.

Their ability to operate quickly and reliably makes them essential for maintaining comfort and energy efficiency in homes, offices, and commercial buildings.

Medical equipment

Also relies on solenoid valves for accurate and safe fluid control. Devices such as ventilators, dialysis machines, and anesthesia systems use solenoid valves to manage the flow of air, oxygen, or medication.

In laboratory settings, solenoid valves help control the movement of samples and reagents in automated testing machines.

Their precision and reliability are critical in medical applications where even a small error can have serious consequences.

Because they can be made from materials that resist corrosion and contamination, solenoid valves are well-suited for sterile environments.

Agriculture

Solenoid valves are used in irrigation systems to automate the watering of crops. These valves can be connected to timers or moisture sensors to open and close based on soil conditions or scheduled intervals.

This helps conserve water and ensures that plants receive the right amount of hydration. Solenoid valves are also used in equipment that dispenses fertilizers or pesticides, allowing for controlled application and reducing waste.

In milking machines, solenoid valves help regulate the flow of milk and cleaning fluids, improving hygiene and efficiency on dairy farms.

Fire suppression systems

Often include solenoid valves to control the release of extinguishing agents. In sprinkler systems, solenoid valves remain closed until a fire is detected.

Once triggered, they open to allow water or foam to flow through the pipes and reach the affected area.

This rapid response helps contain fires quickly and minimize damage. Solenoid valves are also used in gas-based fire suppression systems, where they release inert gases to smother flames without damaging sensitive equipment.

Vacuum systems

Solenoid valves are used to control the flow of air and maintain pressure levels. These systems are common in laboratories, semiconductor manufacturing, and packaging industries.

Solenoid valves help create and maintain vacuum conditions by opening or closing pathways for air to enter or exit.

Because they can operate without requiring high pressure, direct-acting solenoid valves are especially useful in vacuum applications.

Water treatment plants

Water treatment plants use solenoid valves to manage the flow of water through various stages of purification.

These valves help control the addition of chemicals, the movement of water between tanks, and the operation of filters.

By automating these processes, solenoid valves improve efficiency and ensure consistent water quality.

They are also used in sewage treatment facilities to regulate the flow of wastewater and prevent contamination.

Food and beverage processing

Solenoid valves are used to control the flow of ingredients, cleaning fluids, and steam.

They help automate tasks such as filling containers, mixing ingredients, and sterilizing equipment.

Because hygiene is critical in this industry, solenoid valves are often made from stainless steel and designed to be easy to clean.

Their ability to operate quickly and accurately makes them ideal for high-speed production lines.

Pharmaceutical manufacturing

This also benefits from the use of solenoid valves. These valves help control the flow of liquids and gases during the production of medicines.

They are used in processes such as mixing, filling, and packaging. Solenoid valves ensure that the correct amount of each substance is used, which is essential for maintaining product quality and safety.

Their reliability and precision make them a key component in automated pharmaceutical systems.

Marine and aerospace applications

Solenoid valves are used to control fuel, hydraulic fluids, and air systems. On ships, they help manage ballast water, fuel transfer, and cooling systems.

In aircraft, solenoid valves regulate cabin pressure, fuel flow, and environmental controls.

These applications require valves that can withstand extreme conditions, such as high pressure, temperature, and vibration.

Solenoid valves are designed to meet these demands while providing reliable performance.